In today's digital age, laptop handbags have become essential accessories for many people. They not only serve as a fashionable statement but also provide a practical solution for carrying laptops and other essentials. Behind every well-crafted laptop handbag lies a meticulous manufacturing process that combines art, precision, and innovation. In this article, we will take you through the journey of how laptop handbags are made, from the initial design concept to the final product that reaches consumers.

Design and Prototyping

The manufacturing process begins with the creation of a design concept. Our team of talented designers stays updated with the latest fashion trends and consumer needs to come up with unique and functional designs. They consider factors such as the target audience, laptop sizes, and desired features. Once a concept is finalized, detailed technical drawings are created, outlining every aspect of the handbag, including its dimensions, structure, and components. Based on these drawings, a prototype is made to visualize the design and make any necessary adjustments before mass production.

Material Selection

Choosing the right materials is crucial for the quality, durability, and appearance of laptop handbags. Various materials can be used, such as genuine leather, synthetic leather, nylon, polyester, and canvas. Each material has its own characteristics and benefits. For instance, genuine leather offers a premium look and feel, while nylon and polyester are known for their lightweight and water-resistant properties. We carefully source materials from reliable suppliers, ensuring they meet our strict quality standards. In addition to the exterior materials, we also select appropriate lining materials, padding, and hardware components to enhance the functionality and comfort of the handbags.

Pattern Making and Cutting

After the design and material selection are finalized, the pattern making stage begins. Skilled pattern makers create precise templates for each part of the handbag, taking into account the design specifications and the properties of the chosen materials. These patterns serve as a guide for cutting the materials accurately. Advanced cutting technologies, such as computer-controlled cutting machines or laser cutters, are often employed to ensure precision and consistency. This helps minimize waste and guarantees that each piece is cut to the exact size and shape required for assembly.

Sewing and Assembly

The sewing process is a critical step in laptop handbag manufacturing. Our team of experienced sewers uses high-quality industrial sewing machines to stitch the various pieces together. Different types of stitches are used depending on the specific requirements of each seam, such as straight stitches for general construction or zigzag stitches for stretchy fabrics. During this stage, the main body of the handbag is formed, along with any internal compartments, pockets, and lining. The padding is also added to provide cushioning and protection for the laptop. Attention to detail is paramount to ensure that the stitches are strong, even, and visually appealing.

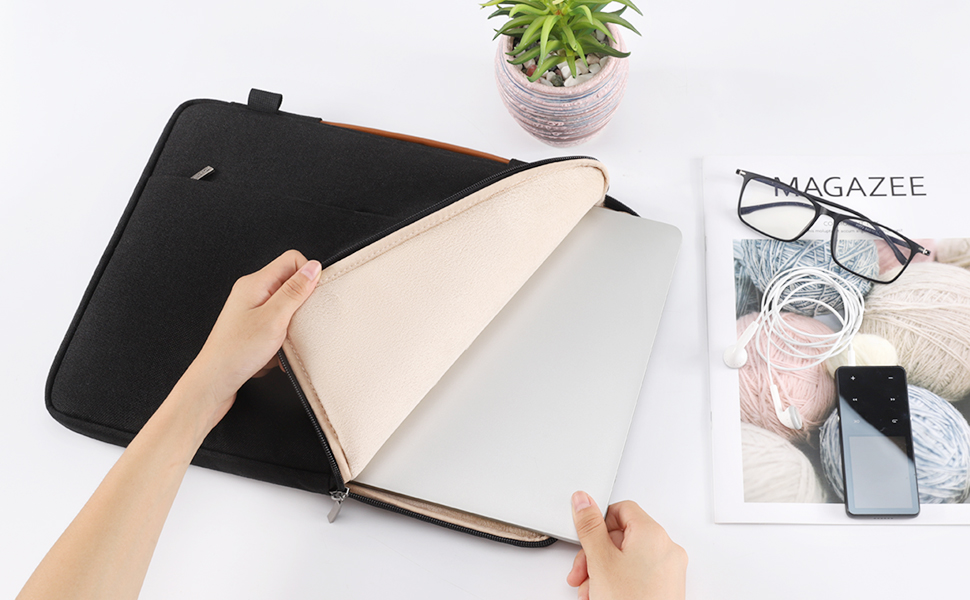

Once the sewing is complete, the assembly process begins. This involves attaching various components such as handles, straps, zippers, buckles, and other hardware elements. Each component is carefully aligned and secured to ensure proper functionality and durability. For example, the handles are reinforced to withstand the weight of the handbag and its contents, while the zippers are tested to ensure smooth operation.

Finishing Touches and Quality Control

After the handbag is fully assembled, it undergoes a series of finishing touches. These may include edge painting, polishing, and applying protective coatings to enhance the appearance and longevity of the product. The edges of the leather or fabric are neatly finished to prevent fraying and give a polished look. Any loose threads are trimmed, and the surface is cleaned to remove any dust or imperfections.

Quality control is an integral part of the manufacturing process. Each laptop handbag is thoroughly inspected at various stages to identify and correct any defects or inconsistencies. Our quality control team checks for issues such as uneven stitching, misaligned components, weak joints, or faulty hardware. Only handbags that meet our stringent quality standards are approved for packaging and shipping.

The production of laptop handbags is a complex and intricate process that requires a combination of creativity, skill, and precision. From the initial design concept to the final quality control checks, every step plays a vital role in creating a high-quality product that meets the needs and expectations of consumers. By continuously improving our manufacturing techniques and maintaining a strong focus on quality, we strive to deliver laptop handbags that are not only fashionable but also functional and durable, ensuring that customers can rely on them for their daily commuting and travel needs.

By following this comprehensive guide to laptop handbag manufacturing, you can gain a deeper appreciation for the craftsmanship and attention to detail that goes into creating these essential accessories. Whether you are a fashion enthusiast, a manufacturer, or a consumer, understanding the production process can help you make informed decisions and choose laptop handbags that offer the perfect blend of style, protection, and functionality.

Harmony Bags has been engaged in bag manufacturing for 20 years. We are a professional company in producing various kinds of bags,such as cosmetic & toiletry bags, backpacks, travel bags, waterproof bags and waist bags. Our monthly production capacity is 500,000 bags. We can guarantee reliable quality, on-time delivery and good service.